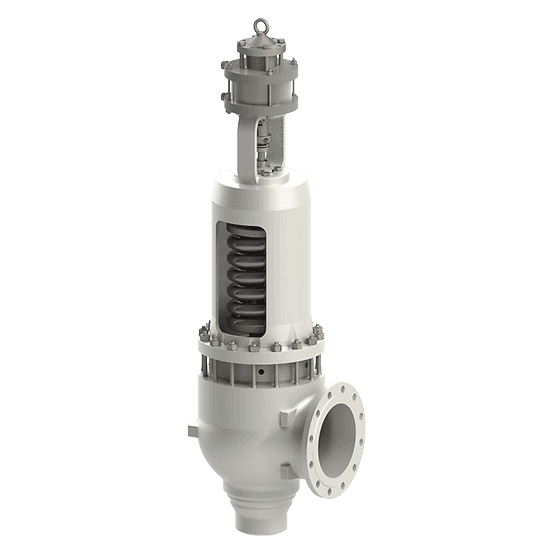

PRESSURE Safety Valve

For participating utilities, GOOD SUPPLIER has supplied PSV’s for twenty-nine (29) nuclear PWR plants. A total of ninety-four (94) valves, including spares, have been supplied for these plants.

The principles of design are the same for

all PSV’s in service or intended for service in domestic PWR’s.

These valves are designed and certified under Section III of the ASME B&PV Code for application in Nuclear Power Systems.

The PSV is a spring loaded safety valve with a bellows and is actuated by a rise of internal steam pressure in excess of a specified value.

The force F4 acts as a closing force because back pressure cannot be eliminated. For low back pressure applications, F4 can usually be ignored. At high back pressures, the effect of F4 is significant since it would affect valve lift and capacity.

In order to provide total system relieving capability under high back pressure conditions, the GOOD SUPPLIER Safety Valve is designed with a patented back pressure compensator piston (part of disc holder) , which utilizes and controls Force F5.

Force F5 acts on the piston in the annular area outside of the guide diameter.

This flow is regulated by the compensator flow ports.

The upper adjusting ring is set at the factory to insure valve lift and capacity even with high back pressures expected in service.

PRODUCT Features

The basic valve model has a design pressure of 2500 psig and a design temperature of 7QQOF. The valve is designed specifically for saturated steam service.

Bodies were originally manufactured from a casting. Material was ASTM A35l Grade 316 stainless steel. Later in valves of the same model number, a body made from a solid forged billet was used. More recent valves, models 31749A-2 and 31709NA-l, have bodies made from a closed die forging.

Material was ASME SA182 Grade F316 stainless steel.

Valve capacity is calculated in according with AS.ME Section III Code with the formula:

W = 5lo5A(l.03P + 14.i) (.975) (0.9) • W = saturated steam, lb/hr

A =orifice area, sqo in.

P = set pressure, psig

Lift is the actual travel of the disc upward along the valve center line when the valve is relieving.

Rated lift is that minimum lift at which a valve attains its rated capacity at a three percent (3%) overpressure (accumulation).

By design, the rated lift for the basic valve model is the lift that provides a certain area equal to the area of orifice bore. Rated lift is calculated by dividing the orifice bore by four.