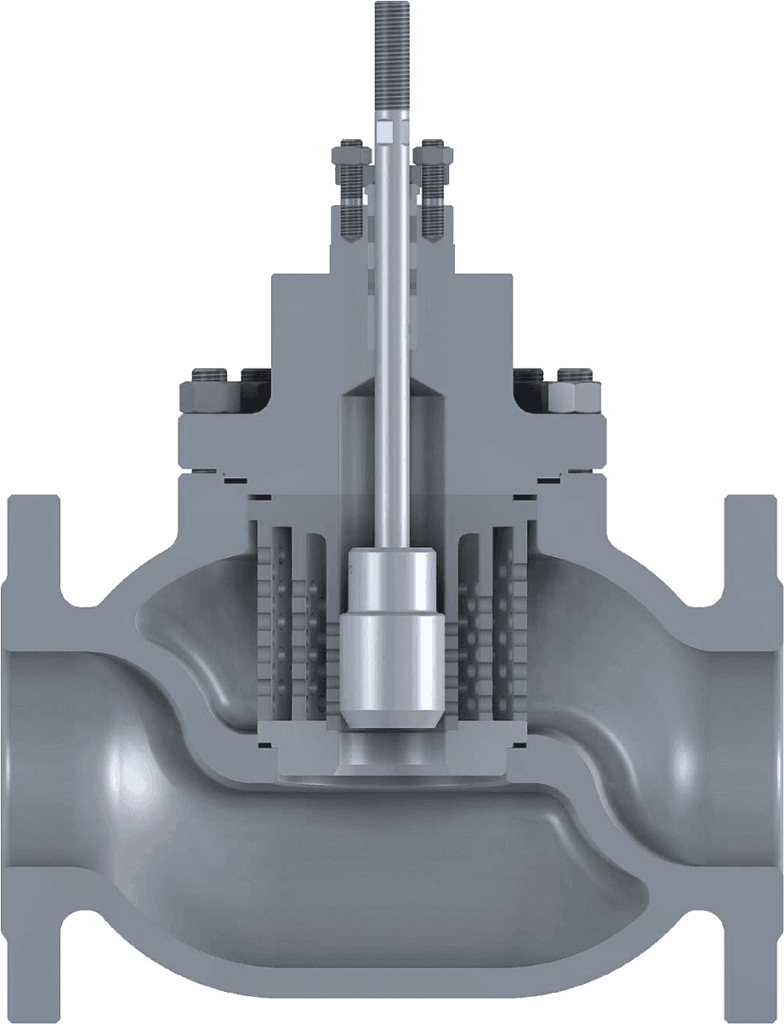

Severe service trim options

⦿ When you think about Good Supplier, this is what you can expect from us: cost effective, high quality, quick delivery, responsiveness.

⦿ Reducing and controlling the effects of cavitation flashing and noise. Our products are made only of appropriate materials, some of which are more resistant to cavitation than others.

⦿ However, often times in order to further increase hardness and toughness of materials, Good Supplier uses its proprietary CVD-5B hardening process, which significantly improves the cavitation resistance of stainless and carbon steels.

This treatment alone is often sufficient for low pressure cavitation.

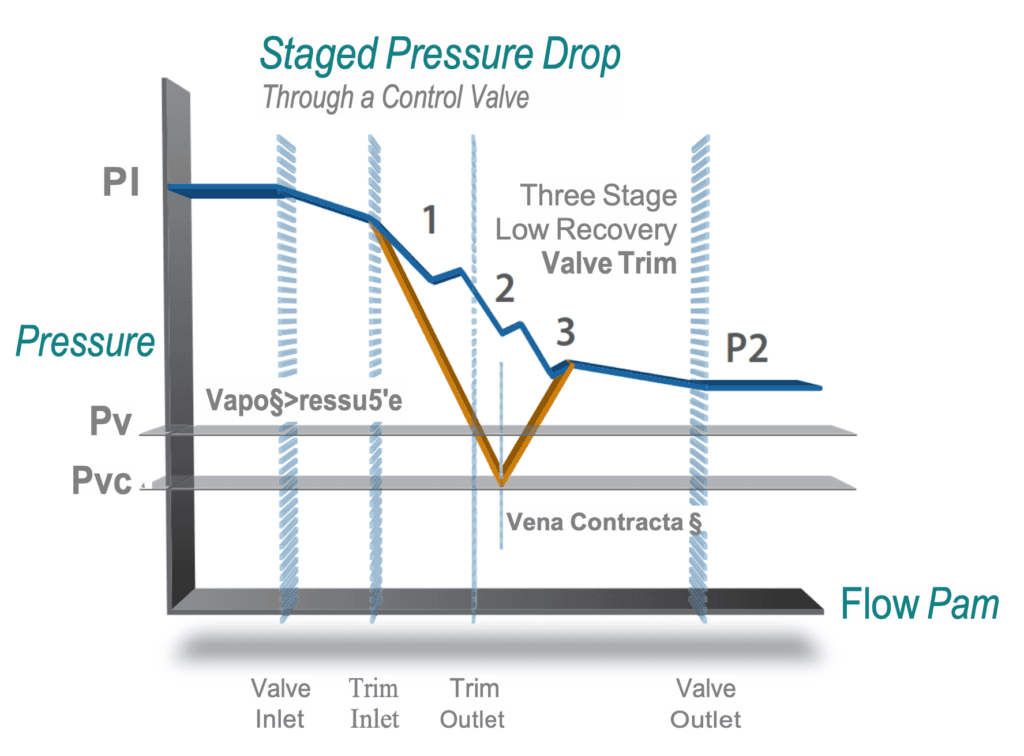

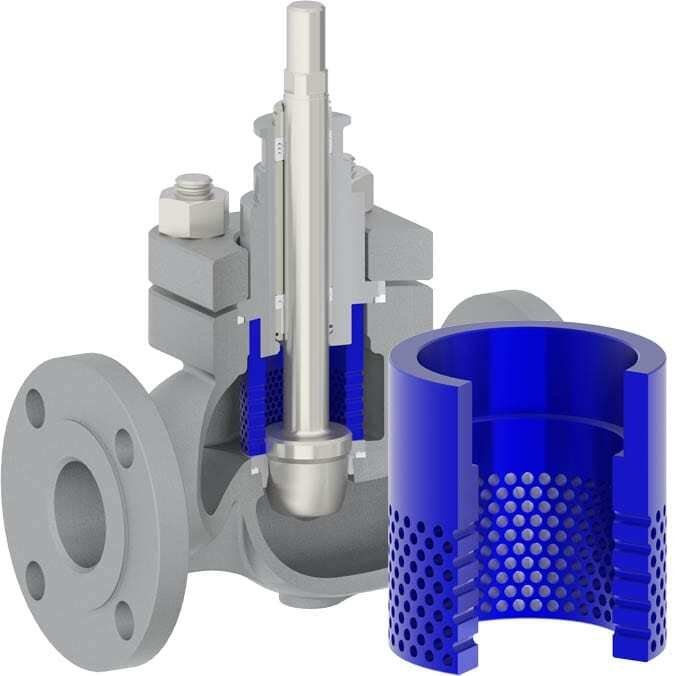

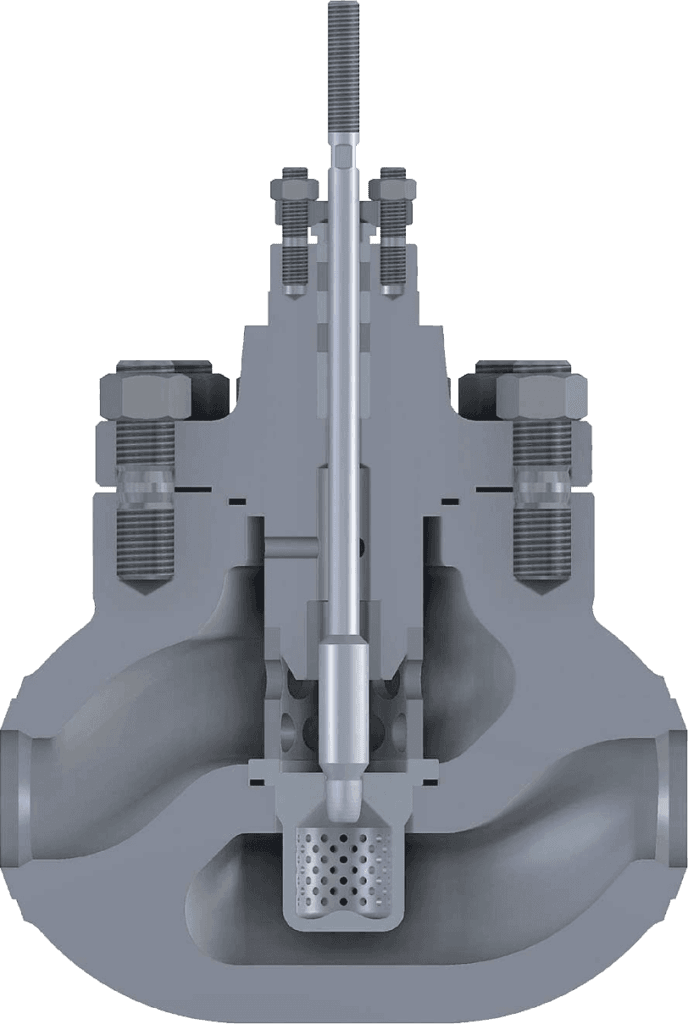

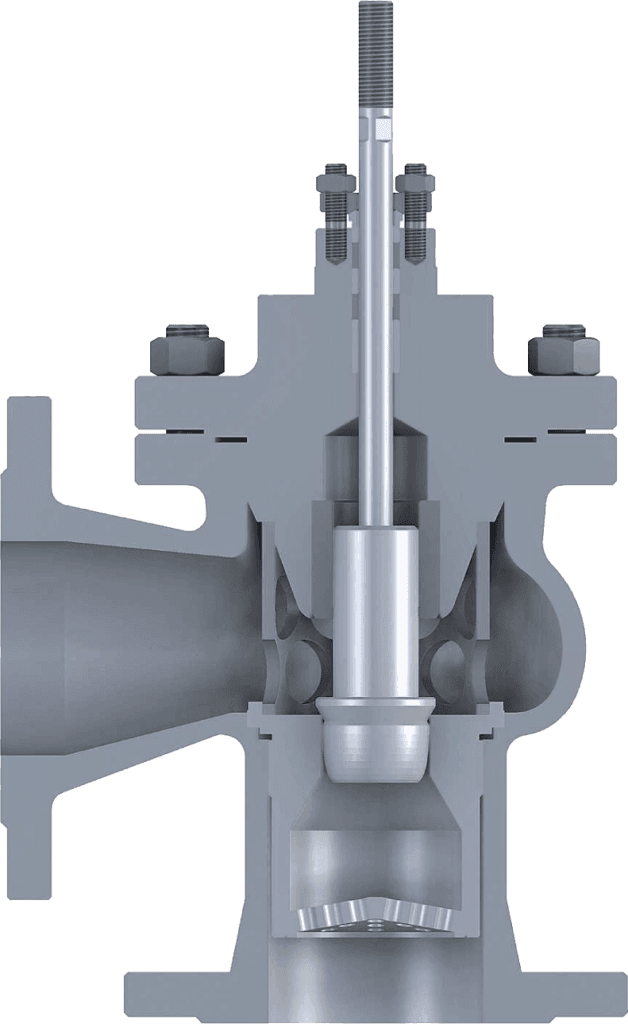

⦿ Similarly, for noisy applications, the focus of the solution to the unwanted noise originating in the valve is through use low-recovery trim packages that break up the flow into smaller flows, as well as multi-stage pressure reducing cylinders.

ST-3 Noise Attenuation trim works to reduce control valve noise in a broad spectrum of gas applications. ST-3 trim has two variants: the first is a one or two-stage design that reduces noise levels up to 15 dBA, the second is a multi-stage design for more extreme noise reduction up to 30 dBA.

ST-3 works by controlling both pressure and velocity of the gas through the valve, thereby reducing turbulence, which is the culprit of all aerodynamic control valve noise. Multi-stage ST-3 reduces pressure with a concentric cylinder design similar to the ST-2 anti cavitation trim.

When ST-3 or ST-4 in-valve noise attenuation trim is insufficient to reduce noise to acceptable levels Good Supplier offers economical downstream devices for additional attenuation: ST-3D Diffusers and ST-3P Diffuser Plates, both capable of noise reductions of up to 25dBA. For more extreme reductions. Good Supplier also offers in-line silencers with the capacity to reduce noise levels by more than 30dBA.

Good Supplier® has harnessed and perfected this advanced technology to, in many cases, effectively extend the life of our valves more than 10 fold.

Good Supplier® is at the forefront of applying innovations in material science to extend the life of its process control equipment. First used in the aerospace industry to harden rocket nozzles on the space shuttle, CVD-5B is a chemical vapor diffusion process using boron wherein a hard wear-resistant metal mesh is fused into the surface of a wide variety of ferrous and non-ferrous materials.